standard torsional test specimen|instron torsion testing : broker Torsion test specimens of dif erent metals for use with TecQuipment’s Torsion Testing Machine (SM1 or SM1001).

Resultado da Trusted By Fortune 500, Globally Language Barriers Simplified Excel in the Global Marketplace Adding Value To Innovative Startups & Large Global .

{plog:ftitle_list}

3D. Clássico. Futebol. Penalidade. Bola. Mouse. Jogue Free Kick Classic (3D Free Kick) gratuitamente na CrazyGames. É um dos nossos melhores jogos de Esportes!

Torsion testing predicts a material’s behavior under twisting forces by assessing key properties such as torsional strength, shear modulus, yield strength in torsion, ductility, and brittleness. It enables the understanding of fatigue behavior, . It involves applying torque to a specimen to measure its response to the applied force. Torsion testing is crucial in understanding the behavior and strength of materials under .

Scope. 1.1 This test method describes the torsion (or twist) testing of metallic wire. 1.2 The values stated in U.S. customary units are to be regarded as the standard. The SI .

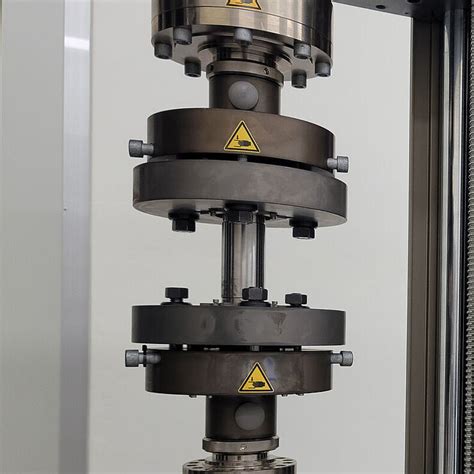

A torsion test is a mechanical testing method that evaluates the properties of materials or devices under stress caused by angular displacement. During a torsion test, a specimen is subjected to a twisting or torsional force, which .Torsion Testing of Structural Metals. Standards. • ASTM E143: Shear Modulus at Room Temperature. Purpose. • To determine the shear modulus of structural metals. Equipment. .

Torsion test specimens of dif erent metals for use with TecQuipment’s Torsion Testing Machine (SM1 or SM1001).1. Scope* 1.1 These test methods cover the tension testing of metallic materials in any form at room temperature, specifically, the methods of determination of yield strength, yield point .

what is torsional testing

This International Standard specifies the method for torsion test at room temperature of metallic materials. The tests are conducted at room temperature to determine torsional properties.

ASTM A938 is a testing standard that describes the torsion (or twist) testing procedures of metallic wire. The results of torsion tests can be used to assess wire ductility under torsional .Tensile testing characterizes the forming and structural behavior of sheet metals. The test involves loading a sample with a well-defined shape along the axis in tension, generally to fracture, and recording the resultant load and .

Measurement of Load and Displacement. All testing systems have some sort of “loading train”, of which the sample forms a part.This “train” can be relatively complex - for example, it might involve a rotating worm drive .

Tensile Test Procedure. A tensile specimen of standard dimensions machined from the metal is inserted in a tensile testing machine (shown in the below figure). . or torsional applications. Based on material .

torsion testing equipment

The main principle of the tensile test is denotes the resistance of a material to a tensile load applied axially to a specimen. It is very important to the tensile test to be considered is the standard dimensions and profiles are adhered to. The typical progress of tensile test can be seen in figure. tensile test done on utm tensile testing machine

ASTM D638 is performed by applying a tensile force to a sample specimen and measuring various properties of the specimen under stress. It is conducted on a universal testing machine (also called a tensile testing machine) at tensile rates ranging from 1 to 500 mm/min until the specimen fails (yields or breaks). Though ASTM D638 measures many different tensile . Specimen Consistency: The ASTM E8 specifies the dimensions and shapes of test specimens. The validity of the test can be compromised by CNC machines that don't follow these specifications, resulting in specimens that aren't uniform. Surface Integrity: Surface integrity can affect the outcome of a test. Surface defects on non-compliant machines .

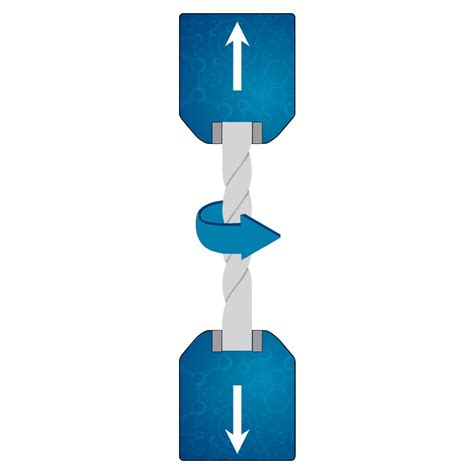

The DIN 50125 standard provides dimensions and examples for tensile specimen measurements in nine different tables. The tables are paired—where necessary—with specimen technical drawings to provide the manufacturing workshop with all required information for specimen preparation when using the DIN 50125 standard.Torsion Only: Applying only torsional loads to the test specimen. Axial-Torsion: Applying both axial (tension or compression) and torsional forces to the test specimen. Failure Testing: Twisting the product, component, or specimen until failure. Failure can be classified as either a physical break or a kink/defect in the specimen. Proof Testing .

A tensile test specimen usually has a ‘dog-bone’ shape and one of the first standards for tensile testing of metallic materials, BS18, was published by the British Engineering Standard Association in 1904 [2].In recent years, there is a trend to miniaturize tensile specimen dimensions often referred to as Miniaturized Tensile Test (MTT) technology.Specimen geometries vary widely depending on the material being tested and the test method or standard being used. Governing bodies such as ASTM and ISO have standardized specimen requirements for different materials, which allows their properties to be reliably compared between different batches and manufacturers.

There are several recognized standards for tensile testing, such as ASTM International's ASTM E8/E8M Standard Test Methods for Tension Testing of Metallic Materials and ISO 6892-1:2016 Metallic materials - Tensile testing - Part 1: Method of test at room temperature. These standards provide guidelines on the test methods, equipment, specimen .This standard documents a straightforward procedure for performing tensile tests on reinforced and unreinforced plastics. The specimen shall be prepared from the plastic material, placed in the tensile tester in such a grip system that prevents slippage in the course of the test, and then loaded until the specimen fails under the tensile test .a) Type A1 and type A2 specimens (1 = injection moulded, 2 = machined from a sheet or shaped article) These are tensile test specimens from which, with simple machining, specimens for a variety of other tests can be taken (see Annex A). The type A1 specimen is a multipurpose test specimen. The principal advantage of a multipurpose test specimen .Test procedure: Specimens are placed in the grips of a Universal Test Machine at a specified grip separation and pulled until failure. For ASTM D3039 the test speed can be determined by the material specification or time to failure (1 to 10 minutes). A typical test speed for standard test specimens is 2 mm/min (0.05 in/min).

torsion testing definition

Furthermore, specimens used in tests on molding materials must be kept in a standard atmosphere (standardized temperature and humidity conditions) for at least 16 hours prior to the test. A standard atmosphere for testing refers to a .of standard dumbbell-shaped test specimens when tested under defined conditions of pretreatment, temperature, humidity, and testing machine speed. 1.2 This test method is applicable for testing materials of any thickness up to 14 mm (0.55 in.). However, for testing specimens in the form of thin sheeting, including film less than

Tensile Testing and Evaluation of 3D Printed PLA Specimens as per ASTM D638 Type-IV Standard. . and tested according to ASTM E8/D638 and E399/D5045 standards for tensile and fracture testing .For the tensile test on rubber and elastomers, ASTM D412 specifies six types of dumbbell specimens and two types of cut ring specimens.; The most commonly used specimen is a C-shape dumbbell specimen (ASTM D412 Type C) with an overall length of 115 mm (4.5 inches), gauge length of 25 mm (1 inch), measurement width of 6 mm (0.25 inches) and thickness of 3 .The tensile test is a test method within mechanical materials testing, used for the determination of material characteristics.Depending on the material, the test is used in accordance with the respective industry standard for determination of the yield strength, tensile strength, strain at break and other material properties.. In the tensile test a material specimen is strained until it .6 Test specimens 6.1 Shape and dimensions Wherever possible, the test specimens shall be dumb-bell-shaped types 1A and 1B, as shown in Figure 1 and Table 1. Type 1A shall be used for directly injection-moulded multipurpose test specimens, type 1B for machined specimens. Type 1A may also be used for compression-moulded specimens.

Jika batang uji berupa round bar maka ditentukan gauge length nya berdasarkan ASTM E8 (Standard Test Methods for Tension Testing of Metallic Materials) adalah 2 in. (50.8 mm). Disertai pembentukan diameter spesimen uji sebesar 0.5 in. (12.7 mm) , radius of fillet 3/8 in. dan Length of reduced section (A) sebesar 2 ¼ in. Pada Gambar 2 berikut . Understanding Torsion TestingIn the field of mechanics and materials science, torsion testing is a crucial method for assessing the strength and behavior of materials under twisting forces. This comprehensive guide will provide an in-depth understanding of torsional testing, the machines used, and their applications in evaluating the performance and reliability .A torsion test is a mechanical testing method that evaluates the properties of materials or devices under stress caused by angular displacement. During a torsion test, a specimen is subjected to a twisting or torsional force, which induces a torque. This test is used to measure various mechanical properties of materials, including their modulus of rigidity, shear stress, .Both the load (stress) and the test piece extension (strain) are measured and from this data an engineering stress/strain curve is constructed, Fig.3.From this curve we can determine: a) the tensile strength, also known as the ultimate tensile strength, the load at failure divided by the original cross sectional area where the ultimate tensile strength (U.T.S.), σ max = P max /A 0, .

uniaxial tension and compression tests

The necking region will occupy a much larger portion of the 1-in gauge length of Specimen B compared to the portion occupied on the 2-in gauge length of Specimen A. When the test is over and the two fractures of the specimens are fitted together, the measured percent elongation of Specimen B with the smaller gauge length will be greater than . in butt joints and the bend testing of surfacing welds. The standard gives the requirements for bend test specimen preparation, test parameters and testing procedures but does not specify the bend radius requirements or accep-tance criteria. 1.2 The base materials may be homogenous, clad or otherwise surfaced, except for hardfacing.

Miniaturized Tensile Test (MTT) is one of the most widely used methods of SSTT [19], which uses specimens spanning several millimeters to hundreds of microns in the smallest dimension (thickness or diameter).However, MTT faces great challenges from specimen size effects and high sensitivity to measurement errors, as well as high demands for operation .

uniaxial testing compression stress distribution

WEBCall us. Questions? No worries! Our support team is ready to assist. Find quick answers in our FAQs or reach out via chat, email, or phone. 📞📧.

standard torsional test specimen|instron torsion testing